Structural Carton Design & NPD Support

Engineered In-House. Built for Performance

At Boxkraft, structural carton design is developed entirely in-house — supporting NPD and product development teams from concept to full production.

Our structural carton design process ensures packaging performs in transit, on shelf and on high-speed packing lines.

Why Structural Carton Design Matters

Effective structural carton design reduces material waste, improves packing efficiency and strengthens supply chain performance. Early engineering involvement prevents costly rework and tooling delays.

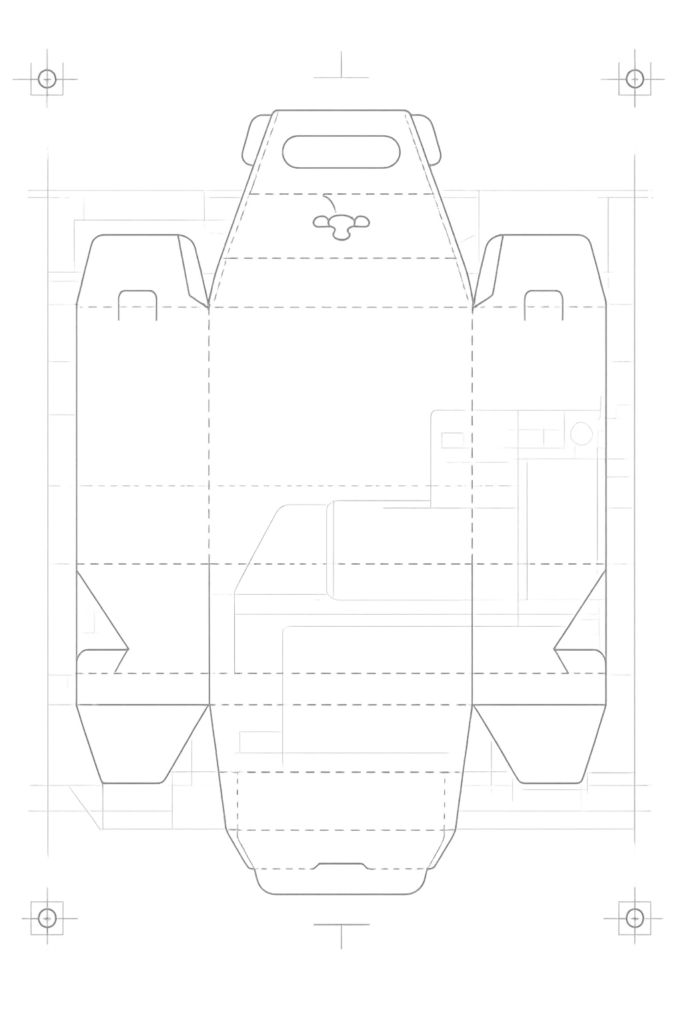

Custom Carton Design & CAD Development

Every structure begins with precision CAD engineering.

We create production-ready dielines tailored to:

- Product dimensions

- Packing line requirements

- Board grade selection

- Retail display objectives

- Export and transit demands

All structural carton designs are created internally for speed, confidentiality and technical accuracy.

Rapid Prototyping with Kongsberg

Our Kongsberg digital cutting table allows fast-turn sample production before steel tooling investment.

This enables:

- Fit validation

- Closure testing

- Shelf simulation

- Transit checks

- Stakeholder approval

Prototype first. Tool second.

Integrated Structural Carton Design & Manufacturing

Our structural carton design team works directly with our print and finishing departments, ensuring engineered concepts move efficiently into production.

By integrating structural carton design with litho printing, die-cutting and finishing capability, we maintain control over quality, tolerance and repeatability.

This integrated approach reduces risk, shortens development cycles and protects brand integrity.

From Dieline to Production Tooling

Approved structures transition directly into precision die-cut tooling.

With structural design and production under one roof, engineering intent is preserved — delivering clean creases, accurate locking systems and consistent performance at speed.