Frequently Asked Questions

What is litho-laminated packaging?

Litho-laminated packaging in New Zealand typically involves high-resolution offset print bonded to corrugated board, delivering retail-quality graphics with the strength needed for transport, stacking and export.

It’s a popular choice for FMCG, wine and beverage packaging, as well as subscription boxes and shelf-ready trays, where presentation and performance both matter.

We’ll advise whether litho is the right fit for your product and supply chain.

What are your typical lead times?

As a guide:

- New custom cartons: 4–6 weeks from artwork sign-off

- Repeat runs: typically 3–5 weeks

- Samples / dummies: usually 5–10 working days

Lead times can vary depending on:

- Board availability

- Print complexity

- Finishing requirements (lamination, foiling, spot UV, etc.)

👉 We’ll always confirm timing upfront — no surprises mid-job..

How do you manage timelines and risk?

We don’t rely on best-case scenarios.

Timelines are built around confirmed board supply, press availability and finishing capacity — not assumptions.

You’ll get a realistic schedule upfront, and we’ll flag risks early rather than rushing late.

How do you support NPD and new product launches?

We regularly support NPD teams from concept through to launch.

This includes early advice on carton style, board selection, print method and finishes — helping avoid over-specification, delays or costly rework later.

If timelines are tight, we’ll guide decisions to keep the project moving without compromising quality.

Proofing & 3D prototypes

Do you offer proofing and 3D prototypes?

Yes. Proofing and prototypes are a key part of managing risk.

Depending on the project, we can provide:

- Plain white dummies to confirm structure and fit

- Printed samples to review graphics and finishes

- Pre-production checks before full runs

This helps identify issues early — before plates are made or volume is committed

What board grades do you use?

We select board based on performance, not habit.

Common options include:

- Solid fibre board (clean retail finish)

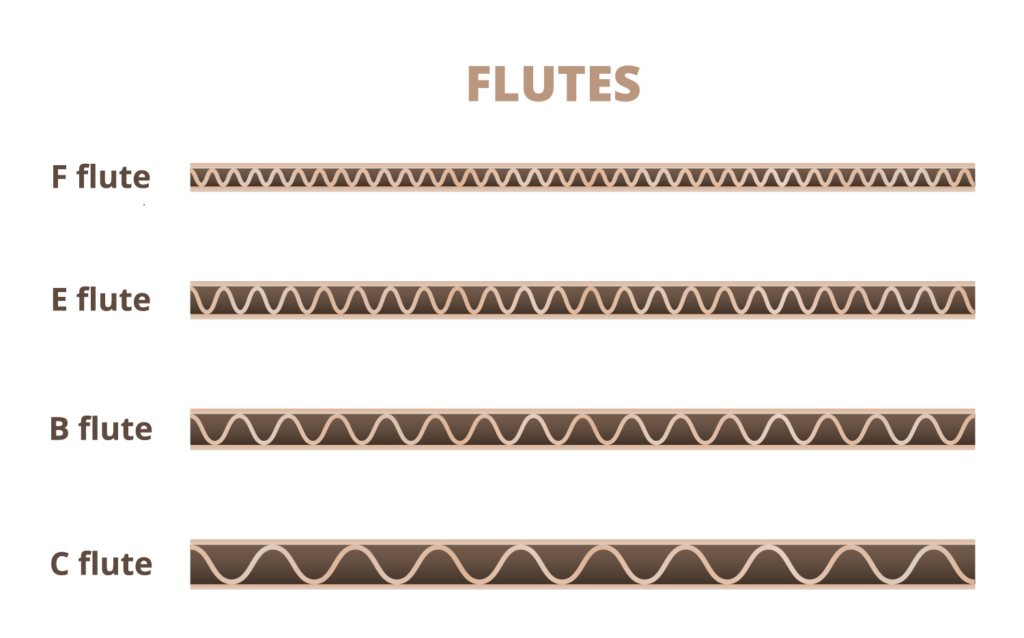

- E-flute / B-flute / C-flute corrugated

- Combination boards for strength + presentation

Board is specified by microns, flute profile and liner weight, depending on:

- Product weight

- Transit conditions

- Shelf life

- Export requirements

We’ll recommend the board — you don’t need to guess.

On-site press passing

Yes. For key projects, on-site press passing can be arranged.

This allows final colour, finish and detail checks to be signed off live, giving confidence before the job moves through lamination and conversion.

Can you work to an existing carton specification?

Yes. If you already have a carton specification, we’re happy to work to it.

Where appropriate, we may suggest alternatives — but any changes are discussed, not assumed.

Delivery & reach

Where do you deliver to?

We deliver throughout New Zealand and support export packaging requirements where needed.

If your product is heading offshore, we’ll consider transit conditions, stacking and shelf life as part of the carton specification.

Who will I be dealing with?

You’ll deal with a real person who stays across your job from enquiry through to production.

We believe clear communication and early conversations prevent most problems later.

Most issues in packaging come down to assumptions made too late.

Our role is to ask the right questions early — around board, print, timelines and risk — so production runs smoothly.

How do Boxkraft’s litho laminated cartons compare to other suppliers?

Brands choosing litho laminated cartons often compare specialist printers, laminators, and large packaging manufacturers. While each has strengths, Boxkraft is purpose-built for brands that need premium print quality, structural performance, and responsive local production — without enterprise complexity.